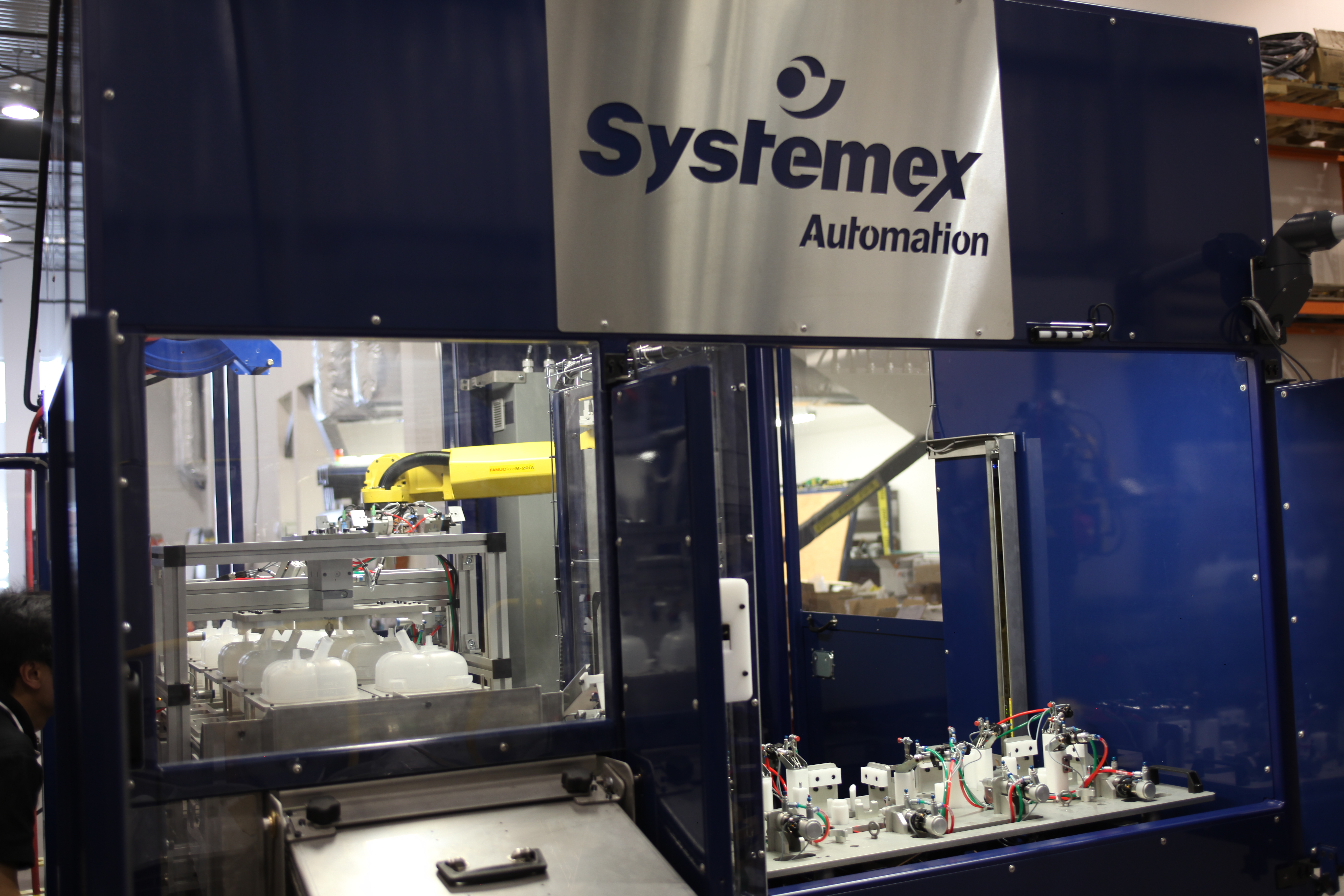

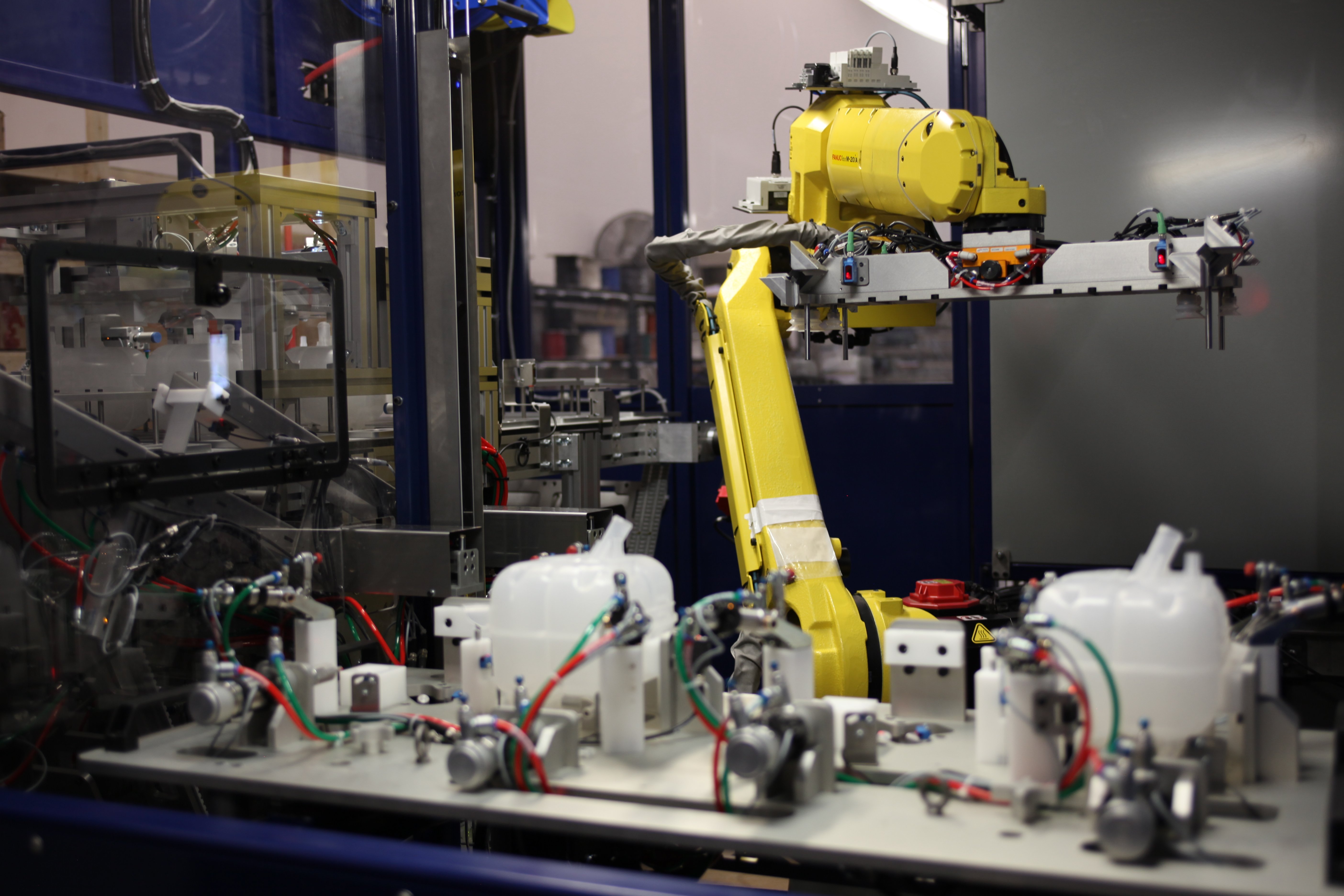

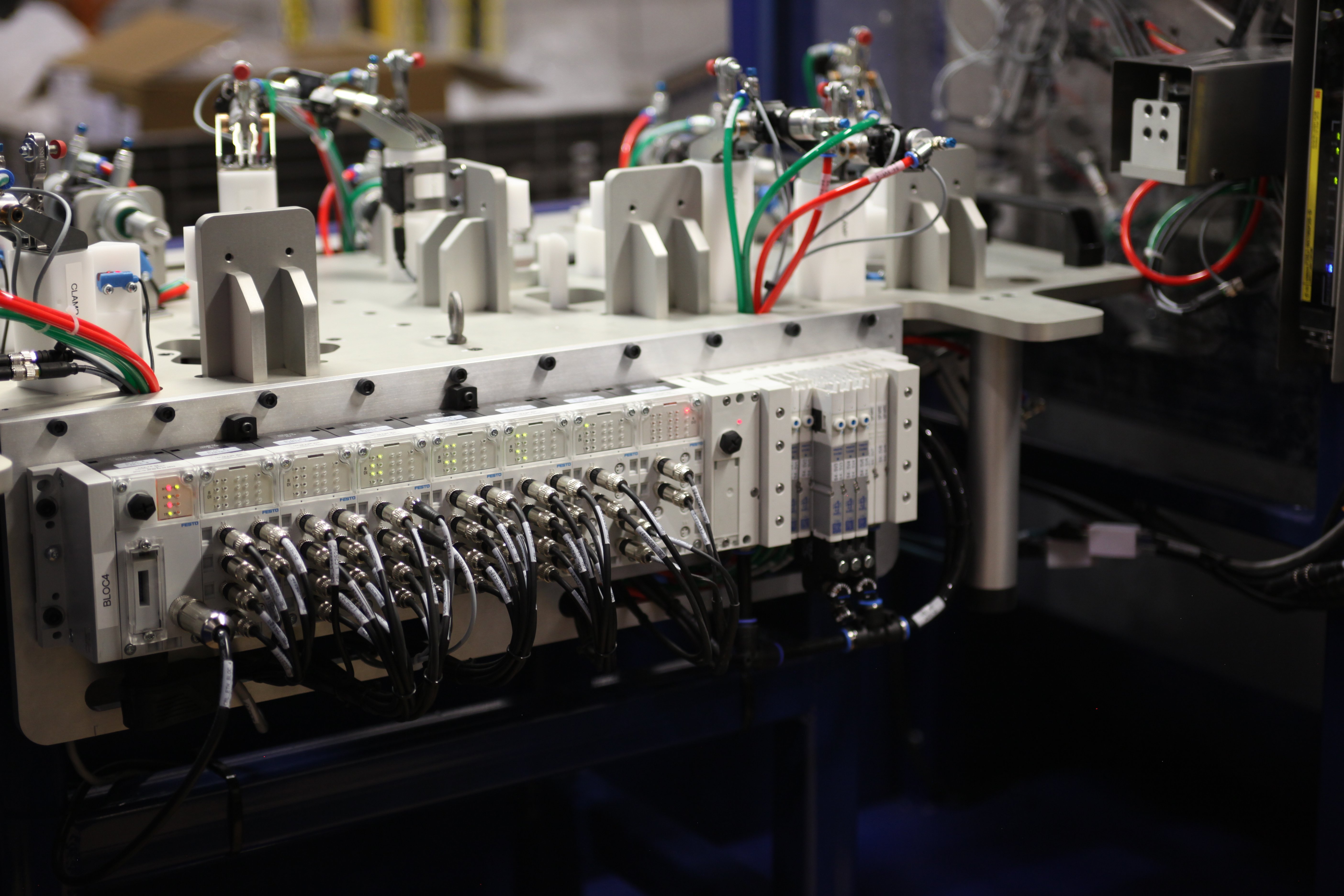

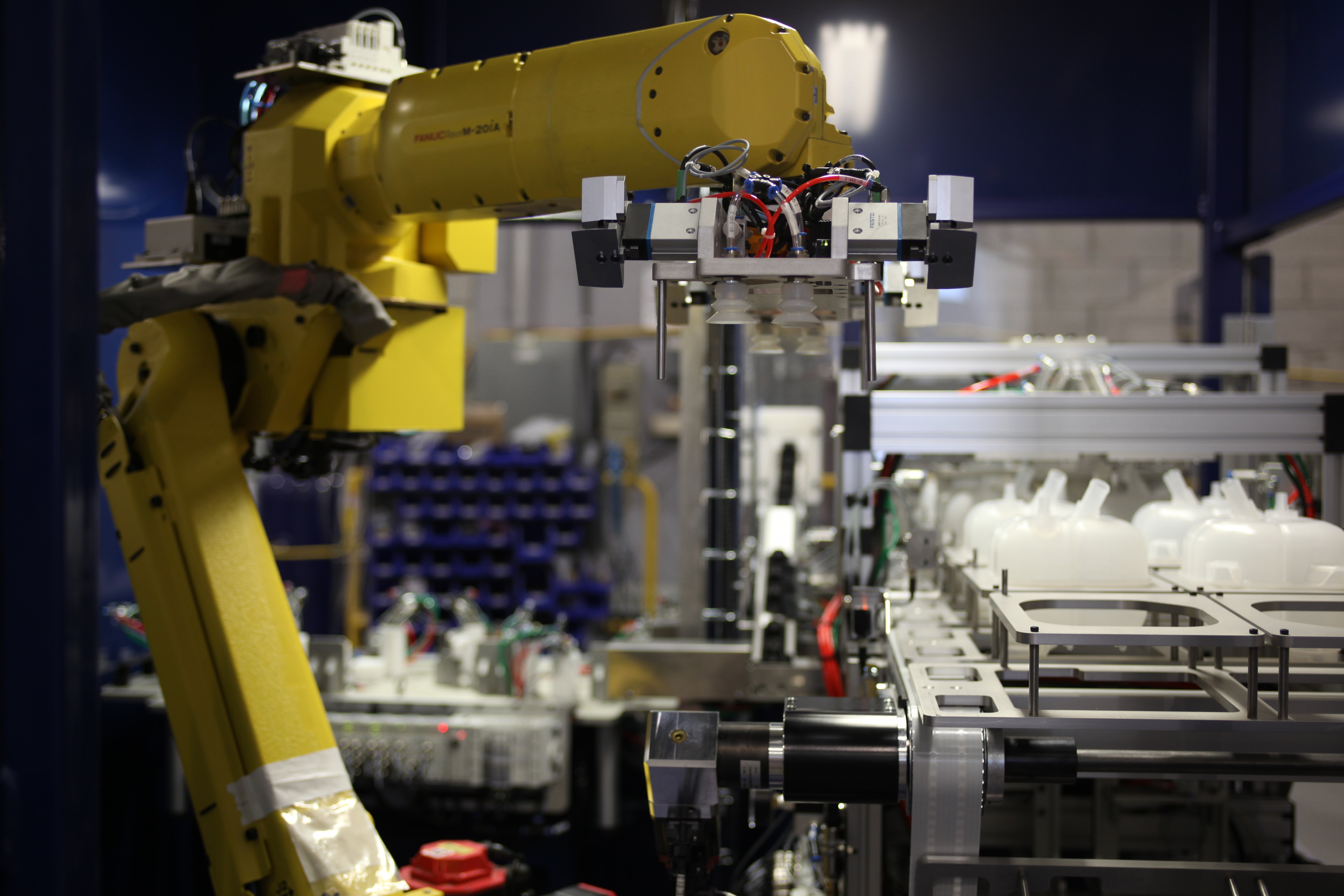

In the context of a leak test project for a coolant tank, the Systemex Automation team designed and manufactured a robotic cell dedicated to inserting parts, performing leak tests and inspecting the coolant tank. The leak test Equipment shall be capable of detecting leaks in the range of 5 sccm to 0,01 sccm on various industrial coolant models, it needed to demonstrate validity and reliability of the leak tests. Also, rabbit parts confirmed the functionality of the robotic cell at each (beginning of shift, change of model). The Red Rabbit part is a known "Failed" coolant tank with a voluntary leak. This validation procedure was accomplished automatically based on a defined programmed sequence.

The robot cell was designed to meet or exceed the following requirements:

- Minimum Overall Equipment Efficiency: 90%

- Availability: 97% (Availability = Run Time / Planned Production Time)

- Performance: 97% (Performance = (Ideal Cycle Time × Total Count) / Run Time)

- Quality: 96% (Quality = Good Count / Total Count)

Systemex Automation also proceeded with the start-up of the unit at the plant located in the Eastern Townships. Thanks to this new robotized cell, the customer was awarded the Supplier of the Year award by General Motors in 2012.

Technical requirements of the mandate:

- 645,000 pieces per year

- Production of 125 hours per week

- Cycle time of ❮ 55 seconds for two tanks

- Interchangeable assembly seats

ACTIVITIES:

- Electrical/mechanical design, programming, start-up

ADVANTAGES:

- Flexibility of the assembly line

- Robotization of the production line

- Interchangeability of the products to be tested

- Accuracy of the tests and reduction of the risks of errors

- Quick return on investment