Smart robotics

A leader in robotics and manufacturing automation, a pioneer in the design of fully modular robot cells, and a visionary in AGV / AMR technology.

CUSTOMIZED ROBOTIC SYSTEMS

All the robotic, automated, mechanical and electrical systems that your plant needs, en route to Industry 4.0.

Automated mechanical and electrical design

AUTOMATED SYSTEMS TAILORED FOR YOUR FACILITY

Systemex Automation ensures the integrated design of automated systems. Our expertise covers all the disciplines required for the development of equipment specific to your application, including mechanical and electrical design, robotics and vision, PLC, DCS and HMI programming, in addition to SCADA and MES applications.

Make an appointment for a free consultation.

Stay informed about customized robotic systems.

Share this information with one of your colleagues.

Robotics & Vision

ROBOTS THAT SEE WHAT THEY DO

Robotic solution can be tailored to your plant, no matter what industry you are in, or what type of application you may need. Let us develop the next innovation that will boost efficiency or safety in your plant, or lower your operating costs. Put our advanced vision technologies to work to identify and report defective products, understand their failures and contribute to rapid and effective intervention in your plant of the future.

Make an appointment for a free consultation.

Stay informed about customized robotic systems.

Share this information with one of your colleagues.

INDUSTRY 4.0

A bridge to the future

Next-generation digital technologies are the best way to address the need for increased business profitability. It has the power to literally digitally transform your manufacturing environment by giving you access to a multitude of business benefits. This will pave the way for a metamorphosis of your plant to become intelligent.

Make an appointment for a free consultation.

Stay informed about customized robotic systems.

Share this information with one of your colleagues.

MODULAR ROBOTIC CELLS

Modular robot cells can make your factory even more flexible and intelligent

INCREASE YOUR PERFORMANCE AND MAXIMIZE YOUR FLEXIBILITY, IT IS NOW POSSIBLE

This latest generation of modular robotic cells™ is an innovation that sets a new standard in flexibility, ergonomics, cost effectiveness and safety for all your manufacturing and automation needs. They offer exceptional modularity in a variety of compact formats for layout in your plant according to your needs. You can integrate the same cells in several production lines by simply moving the robot according to your plant's needs. In short, our cells, like your workers, move, adapt, and perform multiple tasks to maximize the fluidity of your operations, improve your productivity while reducing your costs.

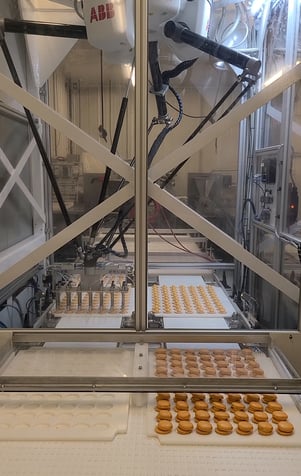

Packing - Case packer

The Packing Modular Robotic Cells™ accurately place products to maximize production efficiency. Fast-paced environments require packaging solutions designed to provide speed, accuracy and reliability while reducing production costs for a rapid return on investment. The solutions can be installed in various types of production environments, whether primary or secondary, without the risk of interruptions or ergonomic problems for operators.

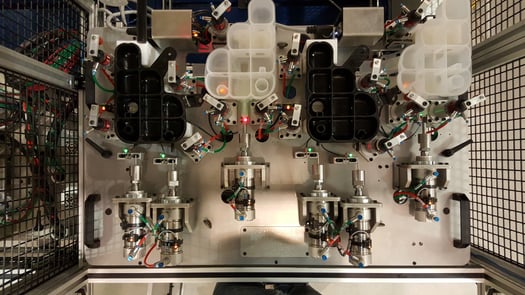

Handling - Assembly

The Robotic modular assembly cells™ accurately place the various components maximizing your production yield. With the help of machine vision solutions and advanced software, we improve the traceability and quality control of your production lines. This flexibility allows you to optimize workflow, increase capacity and easily produce a wider range of products by executing multiple value-added processes, eliminating the need for fixed automation.

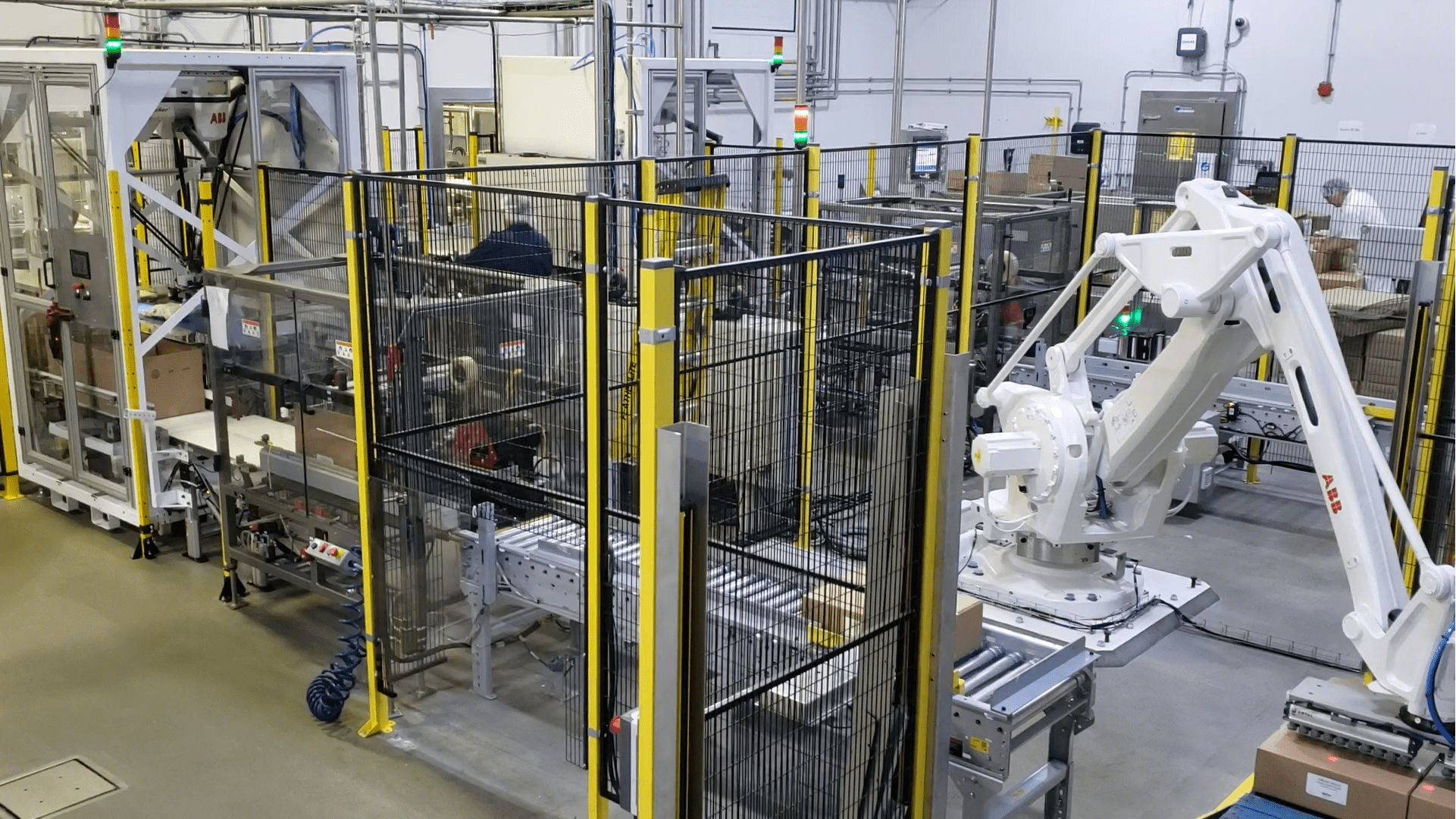

Palletizing

The modular robotic palletizing cells™ can be configured to the desired dimensions and palletizing patterns, making them the most modern and technologically advanced solution in the industry. Since they are modular and therefore versatile, they can be moved easily and according to your production needs, even if these are varied. The modular palletizing software allows you to select production parameters without additional programming or configuration and can work with any modular platform in use in your plant.

AUTONOMOUS MOBILE ROBOTS: AGV/AMR

Autonomous and intelligent mobile AGV/AMR transport systems optimize your logistics processes.

Intelligent warehouse AGV/AMR systems are designed to improve your operational efficiency, with the immediate effect of significantly reducing your costs. They are compatible with your existing processes and systems.

Moving

A very economical alternative to conventional conveyors, AGV/AMR systems can move or transport products or materials within your plant, using an optimal and safe trajectory that adapts in real time to each situation, including storage in an automated storage and retrieval system (ASRS).